Structure Design for SNOUT Stormwater Quality Hoods or Traps

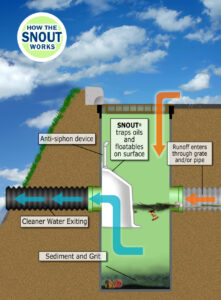

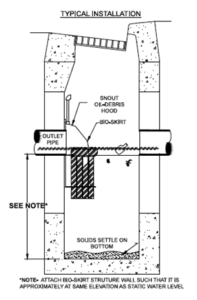

The SNOUT® system from Best Management Products, Inc. (BMP, Inc.) is based on a vented hood that can reduce floatable trash and debris, free oils, and other solids from stormwater discharges. In its most basic application, a SNOUT hood is installed over the outlet pipe of a catch basin or other stormwater quality structure with a deep sump (Download Complete Installation Drawing).

The SNOUT® system from Best Management Products, Inc. (BMP, Inc.) is based on a vented hood that can reduce floatable trash and debris, free oils, and other solids from stormwater discharges. In its most basic application, a SNOUT hood is installed over the outlet pipe of a catch basin or other stormwater quality structure with a deep sump (Download Complete Installation Drawing).

The SNOUT forms a baffle that traps floatable debris and free oils on the surface, while permitting heavier solids to sink to the bottom of the sump. The clarified intermediate layer is forced out of the structure through the open bottom of the SNOUT by displacement from incoming flow. The resultant discharge contains considerably less unsightly trash and other gross pollutants, and can also offer reductions of free-oils and finer solids.

Accessories such as the Bio-Skirt® for oils, the Turbo-Plate® for sediment and T.S.S., and the Stainless TrashScreen™ for Full Trash Capture can be used to increase removals for targeted pollutants.

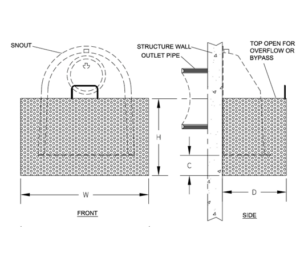

As with any structural stormwater quality device, design of the structure will have a dramatic impact on the system performance over the life of the facility. The most important factors to consider when designing structures with a SNOUT are the depth of the sump and plan area. Sump is defined as the depth from the invert of the outlet pipe to the bottom of the structure. Simply put, the deeper the sump, the more effective the unit will be both in terms of pollutant removals and reducing frequency of maintenance. More volume in a structure means more quiescence, thus allowing the pollutants a better chance to separate out.

Secondly, more volume means fewer cycles between maintenance, because the structure has a greater capacity. Choosing a plan area for the structure of approximately 5 to 7 times the outlet pipe ID will generally yield good results. Also important to good performance is putting SNOUTs in multiple structures. The closer one captures pollution to where it enters the infrastructure (e.g. at the inlet), the less mixing of runoff there is, and the easier it will be to separate out pollutants.

Putting SNOUTs and deep sumps in most inlets that can be easily maintained develops a powerful structural treatment train with a great deal of effective storage volume.

Good Design Best Practices

-

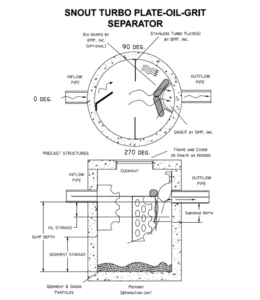

Turbo Plate Installation The SNOUT size is ALWAYS greater than the nominal pipe size. The SNOUT should cover the pipe OD and optimally the grouted area around the pipe (e.g. for a 12” pipe, an 18” SNOUT is the correct choice).

- As a rule of thumb, BMP, Inc. recommends minimum sump depths based on outlet pipe inside diameters of 2.5 to 3 times the outlet pipe size.

- For best performance, the inlet pipe and outlet pipe should have inverts close to the same elevation (a six inch or less deviation is optimal).

- Special note for smaller pipes: A minimum sump depth of 36 inches for all pipe sizes 12 inches ID or less, and 48 inches for pipe 15-18 inches ID is required if collection of finer solids is desired.

- The plan dimension of the structure should be up to 5 to 7 times the flow area of the outlet pipe. Increasing area beyond that has a minimal impact on performance. However, the structure wall where the SNOUT is mounted must accommodate the size of the SNOUT (either the correct diameter or enough width).

- To optimize pollutant removals establish a “treatment train” with SNOUTs placed in as many inlets where it is feasible to do so (this protocol applies to most commercial, institutional or municipal applications and any application with direct discharge to surface waters).

- At a minimum, SNOUTs should be used in every third structure for less critical applications (less critical areas might include flow over grassy surfaces, very low traffic areas in private, non-commercial or non-institutional settings, single family residential sites).

- Use Bio-Skirts® for increased hydrocarbon reduction. Bio-Skirts are highly recommended for fueling or vehicle service stations, convenience stores, restaurants, loading docks, marinas, beaches, schools or high traffic applications. Each Bio-Skirt can retain about one gallon of oils.

- Use the Stainless TrashScreen for “Full Trash Capture” requirements.

- Use BMP Turbo Plates™ for increased sediment and T.S.S. capture.

- The “R” series SNOUTs (12R, 18R, 24R, 30R, 30R/96, 33R, 33R120, 42RTB/60, 52RTB/72, 52RTB/84 and 72RTB/96) are available for round manhole type structures of up to 96” ID; the “F” series SNOUTs (LP318F, 12F, 18F, 24F, 30F, 36F, 48F, 72F and 96F) are available for flat walled structures; the “NP” series SNOUTs (NP1218R, NP1524R, NP1830R, NP1836R and NP2430R) are available for smaller diameter structures up to 36” ID.

Example Structure Sizing Calculation:

A SNOUT equipped structure with a 15 inch ID outlet pipe (1.23 sqft. flow area) will offer best performance with a minimum plan area of 7.4 sqft. and 48 inch sump. Thus, a readily available 48 inch diameter manhole-type structure, or a rectangular structure of 2 feet x 4 feet will offer sufficient size when combined with a sump depth of 48 inches or greater.

Installation Drawings | BIO-SKIRT | STAINLESS TRASHSCREEN

PDF Downloads

Turbo Plate Installation Drawing

BIO-SKIRT Installation Drawing

Stainless Trashscreen Installation Drawing

Contact Information: Please contact T. J. Mullen at 800-504-8008, tjm@bmpinc.com or Matt White at 888-434-0277, mwhite@bmpinc.com for design assistance. Website: www.bmpinc.com

The SNOUT, Bio-Skirt and TrashScreen are protected by: US Patents 6126817, 7857966, 7951294 and 8512556. More US patents are pending and BMP holds Canadian patents for much of the technology patented in the US. Canadian Patents numbers include 2285146, 2688012, 2690156 and 2740678. The SNOUT®, Bio-Skirt® Turbo Plate ™ and Stainless TrashScreen™ are trademarks of Best Management Products.